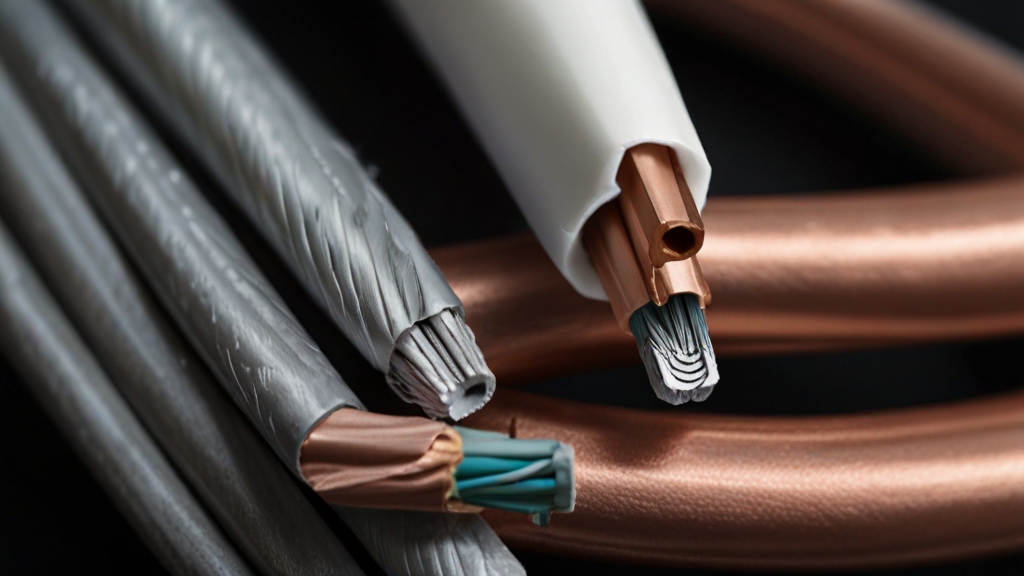

In the world of electrical wiring and cable recycling, the choice between copper cable vs aluminium has been a longstanding debate. Each metal comes with its own set of advantages and disadvantages, making the decision a critical one for various industries. Let’s delve into the intricacies of copper cable vs aluminium. We are going to explore which might be the better choice for wiring and recycling.

Copper Cable for Wiring

- High Conductivity: Copper comes with superior electric conductivity compared to aluminium. This means that it can transmit electricity more efficiently. Overall, this results in lower energy losses and better performance.

- Flexibility: Copper wires are highly flexible, making them easier to install in tight spaces or areas that require bending and shaping. This flexibility also reduces the risk of breakage during installation and maintenance.

- Corrosion Resistance: Copper is naturally resistant to corrosion, which ensures longevity. This also contributes to reliability in different environments, including outdoor applications due to moisture exposure.

- Compatibility: Many electrical components and devices are designed to work specifically with copper wiring. This ensures seamless integration and optimal performance.

However, copper also comes with its drawbacks. Most notably, it’s a higher cost compared to aluminium. Additionally, copper is heavier than aluminium, which can increase transportation installation expenses.

Aluminium Cable for Wiring

In recent years, aluminium has gained traction as a viable alternative to copper in certain applications. Here are some advantages of aluminium cable:

- Lower Cost: Aluminium is significantly cheaper than copper. This makes it an attractive option for large-scale projects where being cost-effective is a priority. This cost-effectiveness can be particularly advantageous in industries such as construction and infrastructure development.

- Lightweight: Aluminium is lighter than copper. This can reduce the overall weight of electrical systems and structures. This is especially beneficial for applications where weight restrictions or transportation considerations come into play.

- High Ampacity: Despite its lower conductivity compared to copper, aluminium cables can still carry high currents. Properly sized aluminium conductors can meet the ampacity requirements of most electrical systems without sacrificing performance.

- Large Conductor Sizes: Aluminium cables can be manufactured in larger sizes compared to copper. This can be advantageous in applications where high current-carrying capacity is required.

Despite this, aluminium has some notable disadvantages. It is more prone to oxidation and corrosion than copper. This can affect its long-term reliability, especially in harsh environments. Additionally, aluminium wiring requires special connectors and installation techniques to migrate the risk of issues such as galvanic corrosion and thermal expansion.

Which is Superior to Recycle

Copper holds a significant advantage over aluminium when it comes to recycling. Copper is highly valued in the recycling industry due to its recyclability without any loss in quality. Unlike aluminium, which degrades slightly each time it’s recycled, copper maintains its integrity and conductivity through multiple recycling cycles. This means that copper cables can be recycled repeatedly without compromising their performance or properties. Additionally, the recycling process for copper requires less energy compared to primary production, resulting in lower greenhouse gas emissions and reduced environmental impact. As a result, copper cable recycling not only conserves valuable resources but also contributes to energy savings and sustainable practices, making it a preferred choice for environmentally conscious projects and industries.

Copper Cable VS Aluminium

Ultimately, the decision between copper and aluminium cable for wiring depends on various factors such as budget, performance requirements, environmental conditions and regulatory standards. While copper remains the go-to choice due to its superior conductivity and reliability, aluminium can offer a cost-effective alternative in certain scenarios.

When it comes to recycling cable, copper holds the position of being the superior metal. Copper Is highly valued in the recycling industry and holds its quality within recycling, unlike aluminium. Furthermore, the recycling process for copper cable requires less energy contributing more to the purpose of recycling… better environment.

Before making a decision, it’s essential to carefully evaluate the specific needs and constraints of your goal. With wiring you need to determine whether it is possible and the better option to go for a cheaper alternative conductor like aluminium. With recycling it’s always good to have the option to recycle both aluminium and copper cables, like us at Event Sparks Cable Recycling. However, if both were on the table and you could only choose one, copper would be the better option.